SRS-150 Residual Ring Shear Testing System for Soils

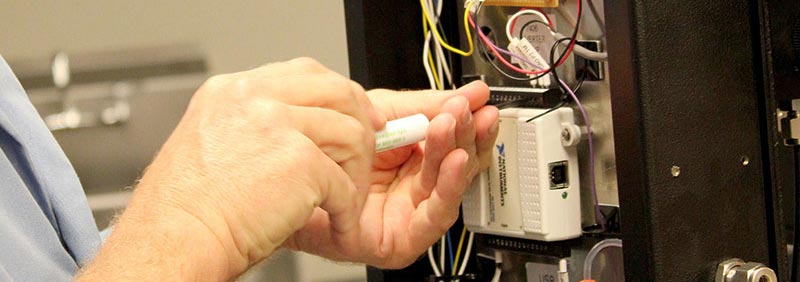

This system features electro-hydraulic closed-loop digital servo control of the shear and normal loads for test automation. Loads or deformations for both the shear and normal actuators can be prescribed for automatically performing conventional ring shear tests as well as more advanced tests. This system can be easily programmed to perform tests such as the constant normal stiffness test where the normal load is a function of a prescribed stiffness for simulating actual compressibility of a ground shear plane (e.g. soil-pile interaction).

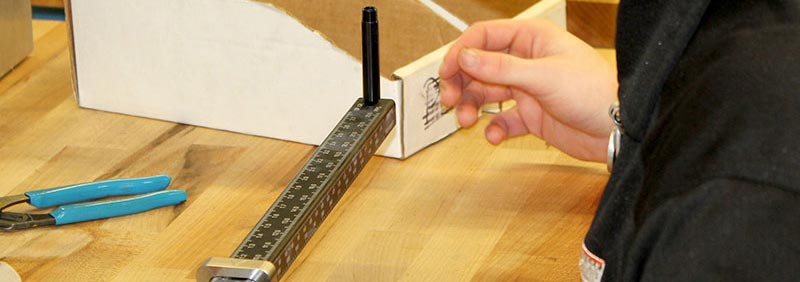

The top shear box has the horizontal translation and the bottom shear box is mounted on pre-loaded sliding bearings to minimize horizontal friction. Set screws with nylon tips are used to adjust the shear gap although the top shear box is suspended on springs that balance its own weight allowing for different shear gaps settings and the precise measurement and control of the normal stress. Included with this system are loading plates with square grid of retractable pins spaced at 25 mm in both directions to grab different type of samples such as soils, asphalt and other materials. Also included is a water reservoir to submerge specimens during testing.

The GCTS Direct Shear Test System is especially well suited to test coarse granular materials and/or simulate interface materials because of its large sample size and high load capacity.

A major advantage of this electro-hydraulic system over conventional motorized system is that this system eliminates vibrations that can disturb or compact granular specimens.

Features

- Zero-backlash computer controlled continuous rotational speed range from 0.001 to 360 degrees per minute (°/min) utilizing Harmonic Drive™ motor technology

- 820 N-m peak, 300 N-m continuous torque capacity

- 10 kN axial load capacity

- 1000 kPa maximum normal stress

- 1300 kPa maximum shear stress

- Compact design, loading frame and motor fit inside the rolling cart for improved safety and space for specimen preparation

- Accepts 6” (150mm) OD 4” (100mm) ID annular specimens