We are excited to announce a new product line focused on automated measurement of fluid properties. This new suite of products will be installed on the rig and will monitor fluid properties in real time.

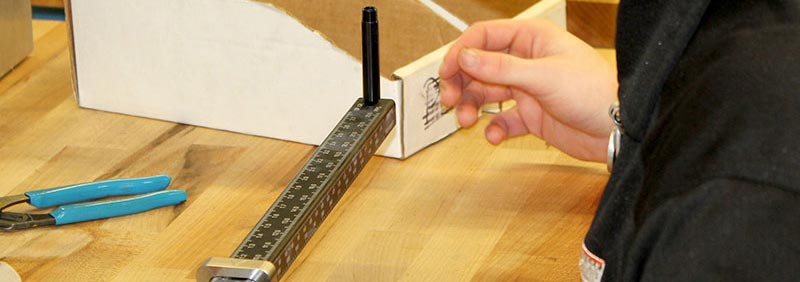

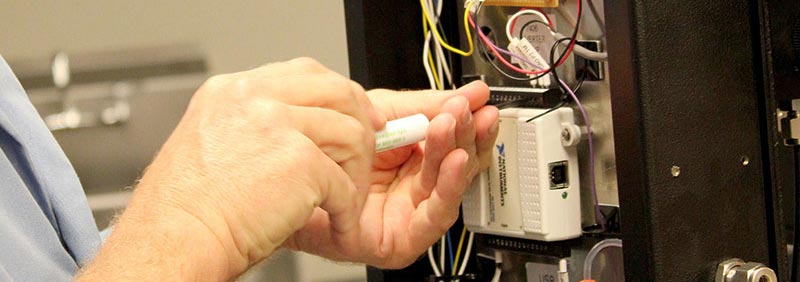

Mud Watcher

The Mud Watcher automatically measures the temperature, density, and viscosity of drilling fluid on the rig and sends the data directly to the rig data acquisition system, mud logging unit, or dedicated data acquisition system. It is designed to be installed, operated autonomously, and maintained by the existing rig crew, with no specialized skills required.

The Mud Watcher provides a steady stream of data, alerting mud engineers to possible problems much more quickly than conventional testing procedures. This reduces risk to personnel while providing accurate and timely measurements to enhance overall decision making, leading to higher efficieny, well quality, and productivity.